The Application of PLC in the Control System of Plastic Recycling Granulator

System Requirements

(1) Extrusion system

The extrusion system includes screw, barrel, hopper, head, and die. The plastic is plasticized into a uniform melt through the extrusion system, and is continuously extruded by the screw through the die under the pressure established in the process. Products.

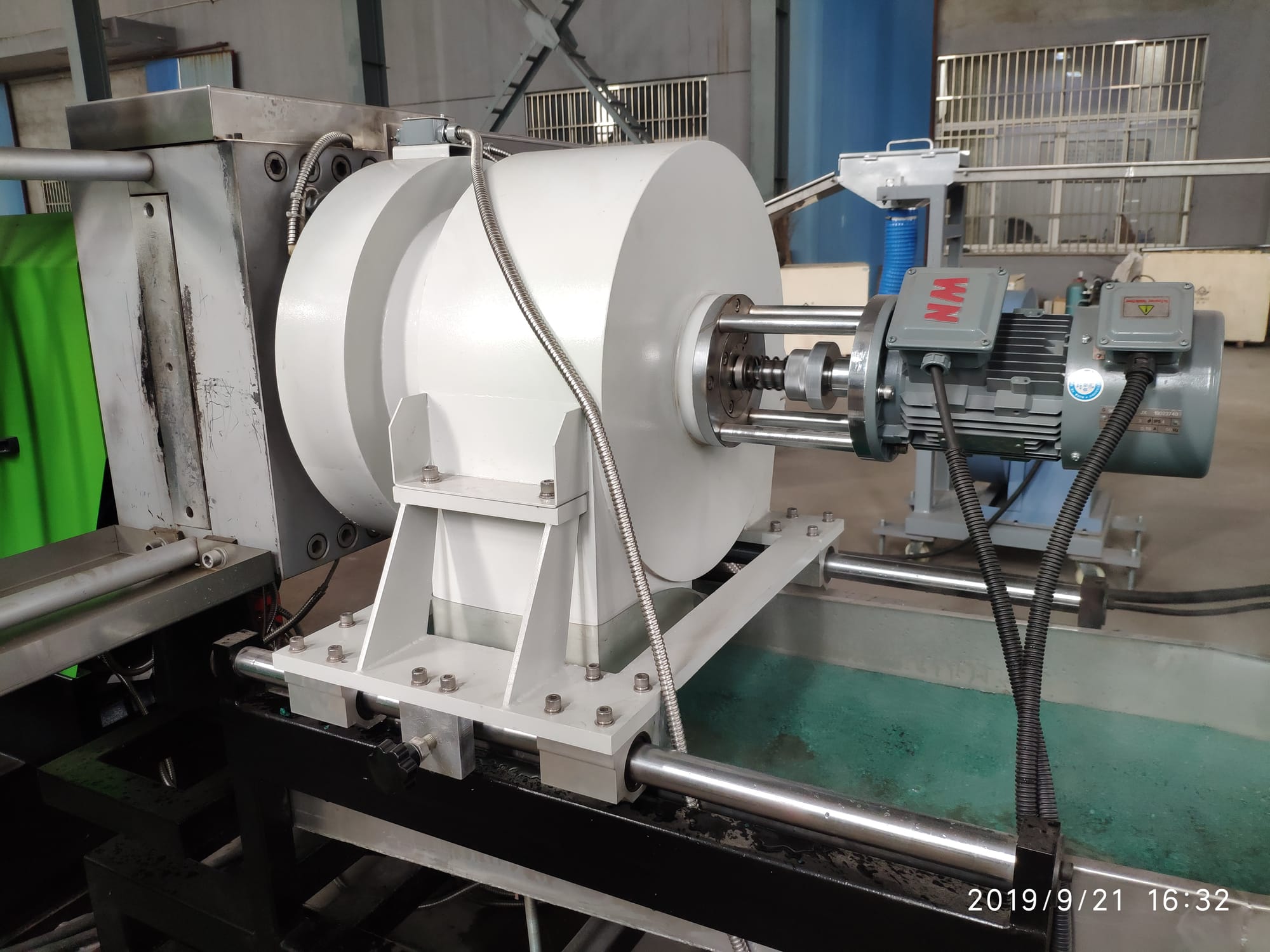

(2) Transmission system

The function of the transmission system is to drive the screw and provide the torque and speed required by the screw during the extrusion process. It is usually composed of a motor, a reducer and a bearing. At present, the most commonly used drive is the frequency converter, and the stability of the frequency converter output is directly related to the stability of the extrusion.

(3) Heating and cooling system

Heating and cooling are necessary conditions in the plastic extrusion process:

1. Nowadays, the plastic recycling granulator usually uses electric heating, which is divided into resistance heating and induction heating. The heating sheet is installed in the body, neck, and head of each part. The heating installation heats up the plastic in the cylinder by an external heating device to reach the temperature required by the process operation.

2. The cooling installation is set to ensure that the plastic is in the temperature range required by the process. Its function is to remove the excess heat generated by the shear friction of the screw rotation to prevent the high temperature from making the plastic synthesis, scorching or shaping difficult. The barrel cooling is divided into two types: water cooling and air cooling. Air cooling is more suitable for ordinary small and medium extruders, and water cooling or two methods are used for separate cooling for large-scale extruders. Screw cooling mainly uses central oil cooling to increase the solid transportation of materials. Rate, stabilize the output, and improve the quality of the product; but the cooling at the hopper is to enhance the conveying effect of solid materials and avoid the plastic particles from sticking and clogging the material opening due to heating, and the second is to ensure the normal operation of the transmission part.