Turning waste into treasure, how waste PET becomes recycled fiber

Polyethylene terephalate (called PET) is a crystalline saturated polyester. It is one of the five major engineering plastics and has a wide range of applications.

Non-fiber grade polyester has applications such as bottles and films, and is widely used in packaging, electronics, medical and health, construction, and automobiles.

Polyester (PET) performance characteristics

Good gloss PET is a milky white or light yellow, highly crystalline polymer with a smooth surface, which can block ultraviolet rays and has good gloss.

Excellent mechanical properties, impact strength of 60-130J/M, excellent folding resistance and good dimensional stability.

Good chemical resistance. It is resistant to oil, fat, alkene acid, alkene alkali, and most solvents.

Good high and low temperature resistance. Melting point is 250-255°C. It can be used for a long time at 120°C. The mechanical properties change little under high and low temperature conditions.

Good safety It has excellent gas, water, oil and peculiar smell performance, good hygiene and safety, and can be directly used for food packaging.

Molding is difficult, the crystallization rate is slow, the molding temperature is high, and the production cycle is longer.

Recycled PET applications

Recycled PET is widely used in recycled polyester staple fiber, recycled industrial yarn, food-grade packaging materials, PET tape, and PET sheet.

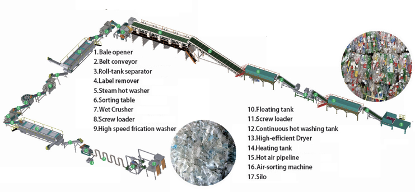

Mainstream equipment for PET recycling

STPLAS MACHINERY washing equipment is specially designed for recycling and recycling of waste mineral water bottles, cola bottles, PET plastic bottles, etc., such as de-standardization, crushing, friction washing, high-temperature cooking, rinsing, dehydration, and drying etc. related auxiliary machines and production lines