2000KG/H PET Bottle scrap Recycling washing machine plant

STPLAS MACHINERY is a creative company, focusing on the technology of plastics recycling and plastic extrusion system. For example, plastic crushing washing drying system for PP PE film, PP PE bags, HDPE bottle, PET bottles etc. We also produce plastic shredder, film squeezing machine, plastic crusher, agglomerator etc.

- Category: PET Bottle Washing Line

Description

PET bottle crushing washing drying recycling line

STPLAS MACHINERY is a creative company, focusing on the technology of plastics recycling and plastic extrusion system. For example, plastic crushing washing drying system for PP PE film, PP PE bags, HDPE bottle, PET bottles etc. We also produce plastic shredder, film squeezing machine, plastic crusher, agglomerator etc.

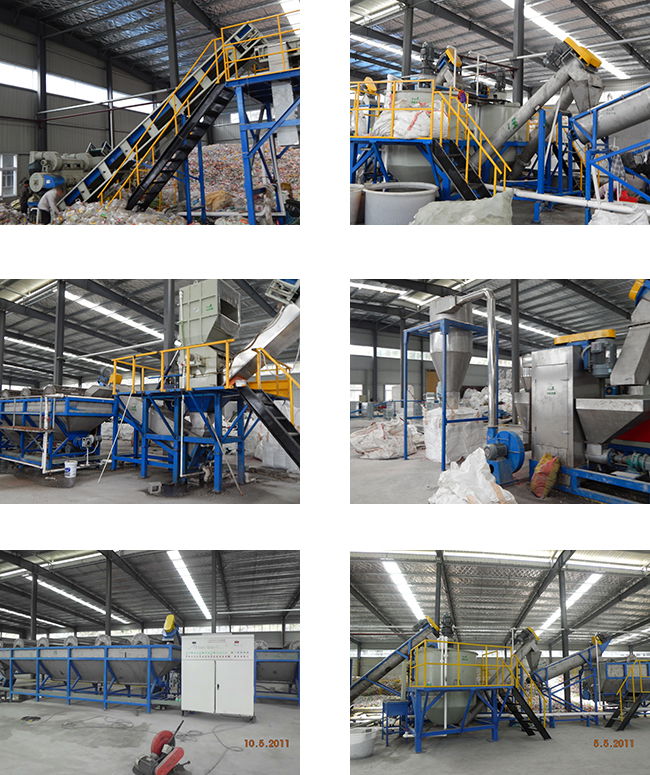

Here are some photos of our complete PET washing line for 1000 kg/h for your reference.

Warmly welcome to visit us!

Product Description

- Capacity of PET bottle washing line: 1000kg/h, 2000kg/h, 3000kg/h, 5000kg/h or according to client's demand.

- Raw Material: Plastic Cola bottles, plastic Pepsi Cola bottles, plastic Mineral water bottles and other bottles which remarked PET.

Advantage for PET bottle scrap washing recycling line :

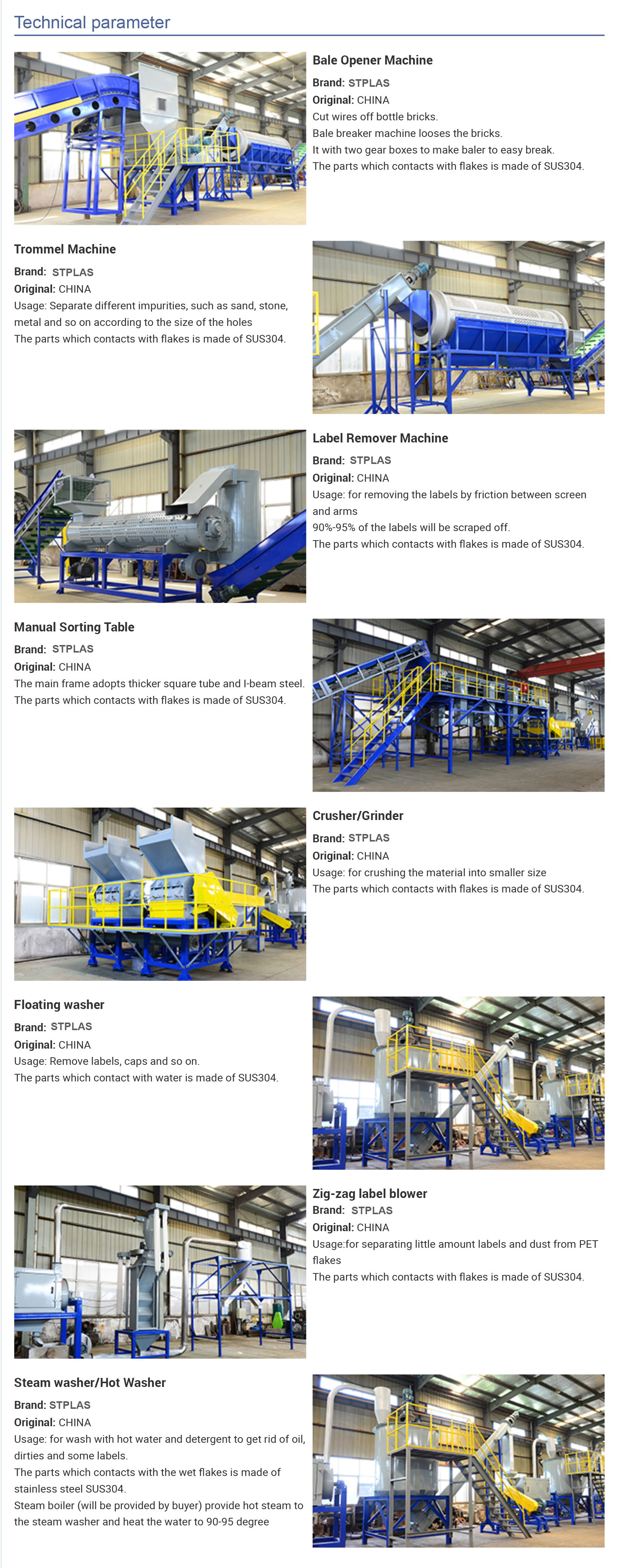

- Hot Washer Steam machine will add Soda inside ,and the temperature should be over 90°. This unit will go though gas ,electric or diesel ,which is more cheaper in your country , you can choose it.

- Label remover machine has two type ,one is with water, the other is without water.

Both of them can take out labels ,and the rate can meet 90%.

- The material which is with water used 304SS ,it make more long life of the line.

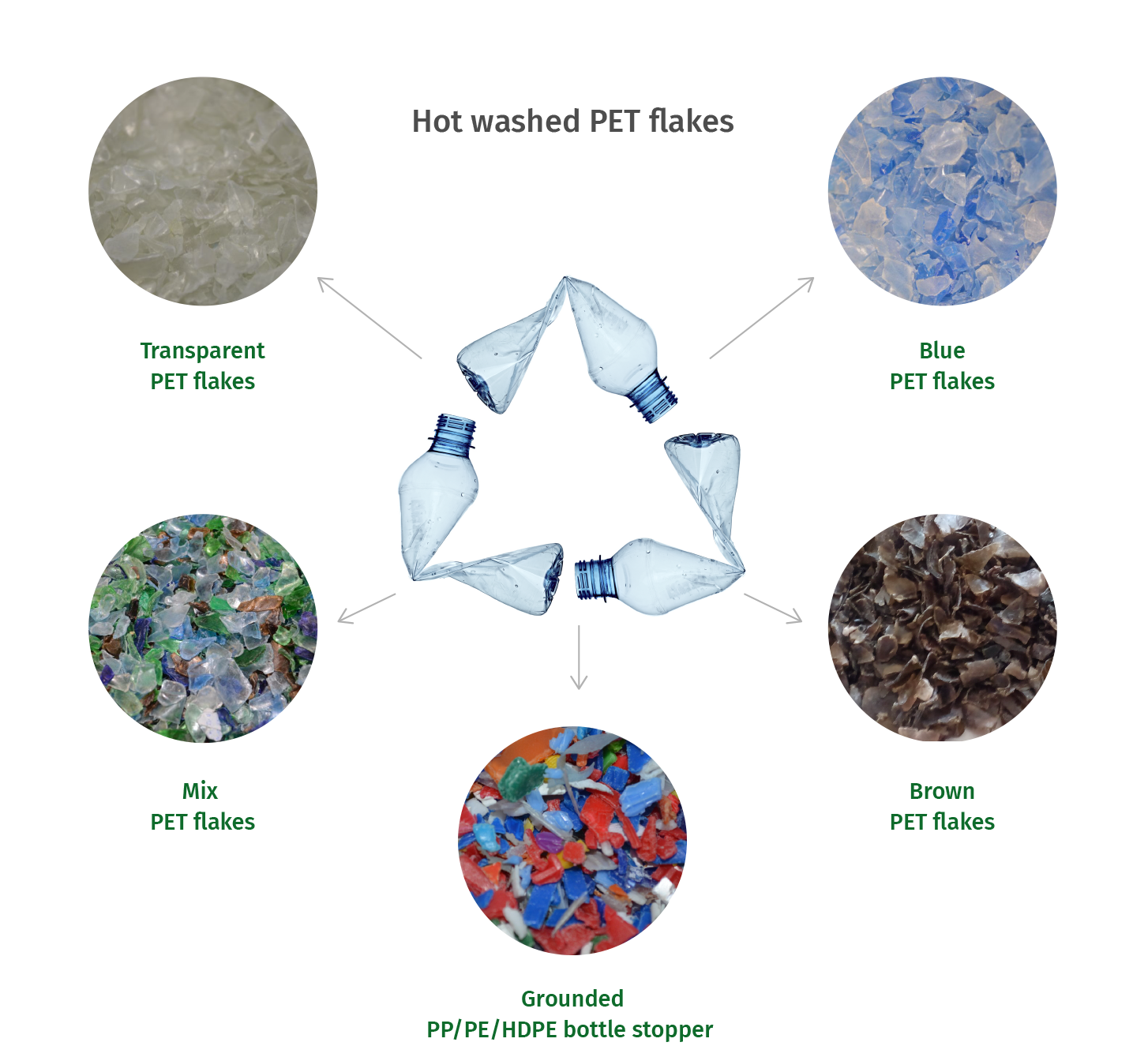

Application of PET flakes:

The clean flakes can be used to produce the polyester staple fiber, PET strap band, granules, PET transparent film and sheets, etc. The top class flakes can be used to blow bottles again.

Final Products:

Moisture: max 1%

Bulk density: 0.3G/CM3

Particle size: 12-18mm or according customer requirement.

Metal content: max.20ppm

Floatable contamination: less than 200ppm

Total impurity: 100-320ppm

Main Technical of PET washing recycling line:

Model | BXPET-2000 |

Capacity(KG/H) | 2000 |

Water consumption(T/H) | 6--58 |

Power Consumption(T/H) | 400--460 |

Staff(person) | 5-6 |

Factory Area (M2) | 110*6*6 |

Above date is only for reference. We design pet bottle recycling line according to different raw material and above date will be different.  PET recycling machine line in our customer factory.

PET recycling machine line in our customer factory.

If you want more details of our waste plastic bottle recycling machine/ plastic pelletizing line, plastic shredder /crusher/ grinder machine, Contact with us freely!