PVC straps sheet plastic crushing machine

PVDC

- Category: Plastic Crusher and Shredder

Description

Scope of application:

Plastics-general plastics such as injection molding, extrusion, blown film, etc.

Rubber-tire rubber, reclaimed rubber, etc.

Cable-copper core, aluminum core cable and composite cable

Chemical fiber-carpet etc.

Sponge-industrial waste, etc.

Machine Introduction:

The heavy-duty crushing machine is designed to meet the production needs of output crushing and one-time crushing of large materials.

In addition, this series of crushing equipment is often used as secondary crushing after the shredder in various production lines.

According to the characteristics of the material, design a good cutting angle, suitable cutting speed, and a wear-resistant design to ensure that the system runs continuously for a long time, so as to achieve the ideal material crushing effect.

Technical Characteristics:

- Compact design, saving space.

- Inclined up and down split box for easy blade replacement

- Hydraulically driven hopper and box opening device for easy maintenance.

- High safety factor bearings, reducing the probability of bearing damage.

- Precise spindle machining (front V-shaped spindle is standard configuration).

- Both ends of the spindle are equipped with replaceable wear plates.

- Standard model can be equipped with air delivery device

Main Technical Parameter:

Model | STC-800 | STC-1000 | SC2-1200 | STC-1400 | STC-1600 |

Number of Fixing Blade (pcs) | 4 | 4 | 4 | 4 | 4 |

Number of rotator Blade (pcs) | 6 | 6(10) | 6(10) | 10 | 10 |

Main Shaft Diameter(mm) | 450(500) | 630 | 750 | 800 | 800 |

Motor Power(KW) | 37 | 55-75 | 90-110 | 110-132 | 160 |

Capacity(kg/h) | 400-600 | 800-1200 | 1300-1600 | 1600-2000 | 2000-2200 |

Features of Plastic crushing machine:

1. Good looking in surface, color coordination, spray-painted solid.

2. Hopper, crushing room, misreported is disserted, easy to dumpster gate.

3. The crushing room use noise arrester, to lower noise.

4. Pulley with guards, so it is safe and reliable.

5. Cleaning and insurance.

6. The motor has a protective device and power chain protection system.

7. The using life of the alloy blade is much longer than the ordinary one,

moreover, it is very suitable for smashing high-densely plastic.

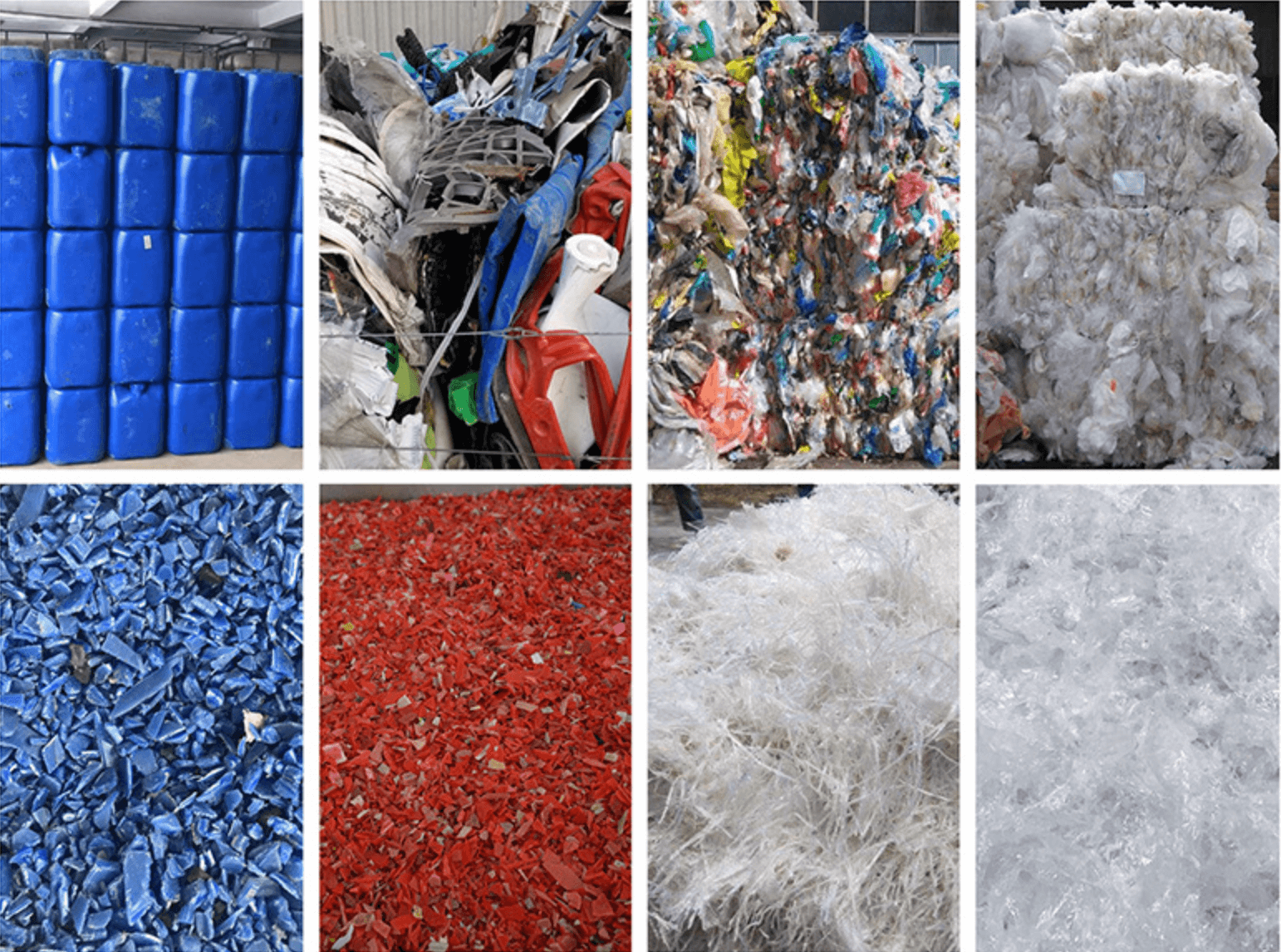

More Photos of the PVC crushing machine