Plastic PP woven bag PE film plastic recycling granulator machine

Name : Plastic PP woven bags, PE films recycling granulator machine Raw material: Plastic PP woven bags, non-woven bags, PE film Usage: machine to recycle waste Plastic PP woven bags, non-woven bags, PE film to granules/pellets. Main Machine: single screw extruder/ Compactor Feeder, pelletizer. Screw: single screw.

- Category: PP PE Pelletizing Machine Line

Description

Plastic PP woven bag/ PE film granulation recycling machine production line features:.

1. Plastic PP woven bag PE film pelletizing recycling machine line, with high output and good pelletizing capacity (200kg/h~1000kg/h).

2. Plastic PP woven bag PE film pelletizing recycling machine line is widely used to recycle waste PP woven bags and non-woven fabrics to make PP particles.

3. Highly automatic: only 2 people in a production line

4. High efficiency: Compared with the first generation power generation design, the second generation PP woven bag pelletizing recycling machine production line will increase the output by 20%

5. Low power consumption: power consumption is 15% lower than the first generation

6. According to the cleanliness of raw materials and actual production needs, you can choose single-stage (one extruder with one screen changer) or two-stage (two extruders with two screen changers)

7. Water ring pelletizing or cooling strip pelletizing can be selected to match different raw materials.

Raw material:

Final products:

How to choose the right machine you want?

Please tell us the details of what you want.

What are your raw materials?

What is the final product you want to produce?

What machinery production output do you want?

How to control the quality? ?

We have technical and engineering teams to design prototype machines before entering the market

Production, QC team to ensure the quality of machine manufacturing

After finishing before shipment, we will run each machine

Customize machine design according to customer's raw material condition.

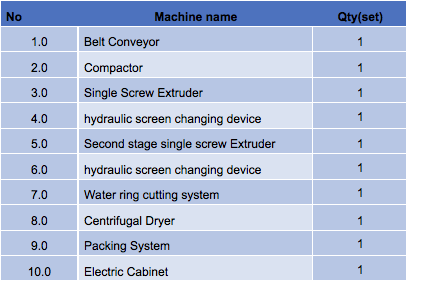

Plastic woven bag film granulation recycling machine list:

Suzhou Stplas Machinery also have rich experience in cooling strand granulation methods, which can be customized according to raw material conditions.