Analysis of the causes of blockage of the plastic shredder feed inlet and its wide range of applications?

1. Poor or blocked pipes may cause blockage of the plastic shredder.

Improper matching of the conveying equipment will also cause the wind in the discharge pipe to be weakened or blocked after no wind.

The solution is to clear the delivery port first, change the mismatched conveying equipment, adjust the feeding amount, and make the equipment operate normally.

2. The blade is broken and aged, the mesh hole is closed and broken, and the water content of the crushed material is too high, which will block the plastic crusher.

Solution: The broken and severely aged blades should be regularly updated, and the screen should be inspected regularly to ensure that the moisture content of the crushed material should be less than 14%.

3. The plastic shredder is not suitable for the plastics to be treated in terms of structural design.

Solution: When purchasing a plastic shredder, it is best to test the materials that you need to break.

4. It may be that the feed rate is too fast and the load is increased, causing blockage.

Solution: The current of the plastic shredder is generally controlled at about 85% of the rated current.

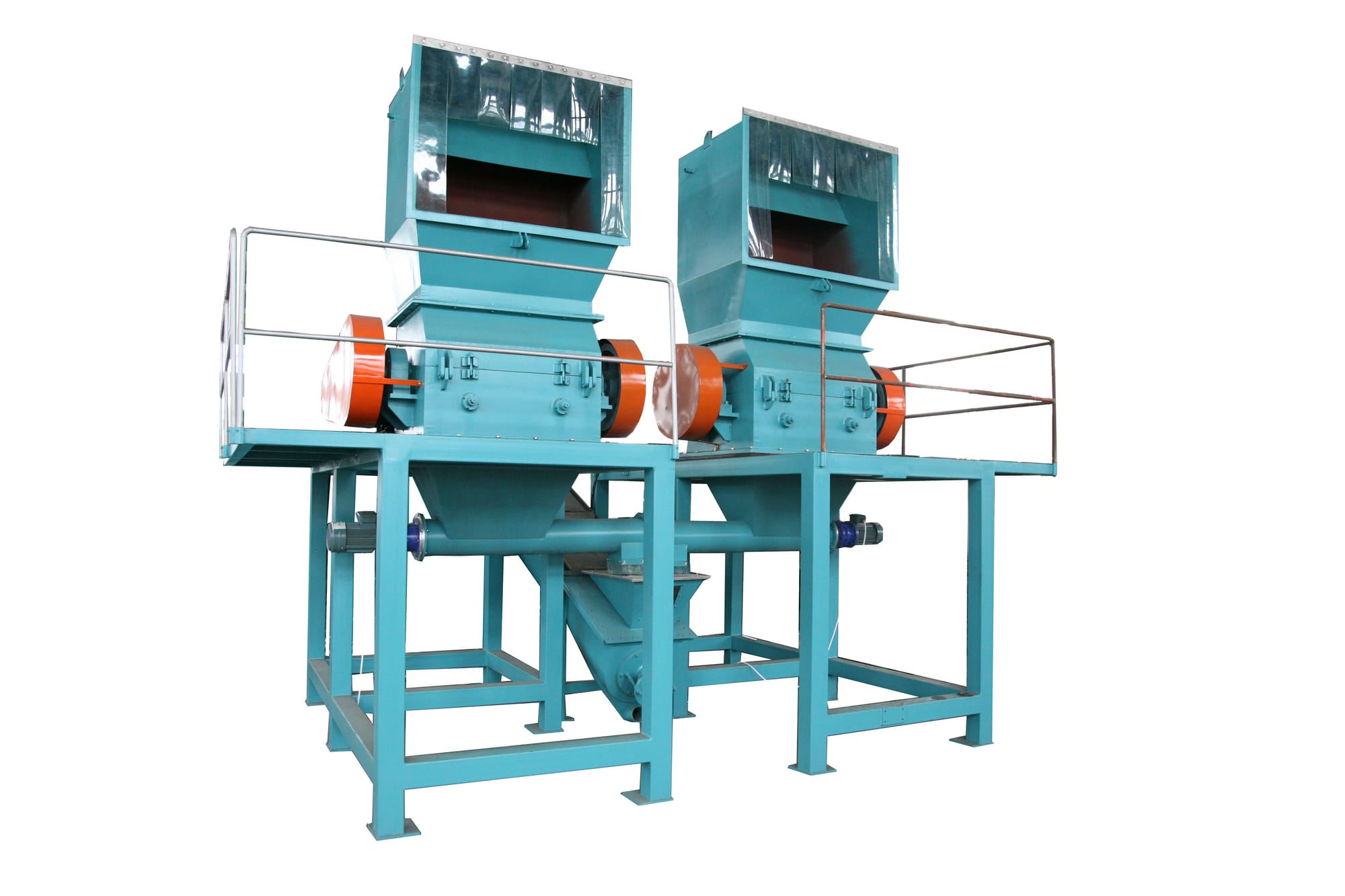

The plastic pulverizer is easy to operate, and the blade change is simple and quick. The wide cutter structure is suitable for crushing large-volume thin-walled and thin material products and improving the crushing efficiency.

With electric control and safety design, the hopper adopts double-layer structure, filled with soundproof material, motor with overload protection device, power supply equipment with good safety and environmental protection, saving electricity and durability.

The plastic pulverizer is suitable for the recycling of plastics such as boxes, thin pipes, blow moldings, bottles and shells. Plastic factory, electronics factory, plastic container factory, lighting factory, shoe factory, electrical factory, auto parts factory, luggage factory, pumping factory, waste recycling factory, plastic furniture factory, plastic cabinet factory, ABS, PMMA, POM, nylon , hard rubber head, horns, fiber materials and other hard plastics and other crushing process.