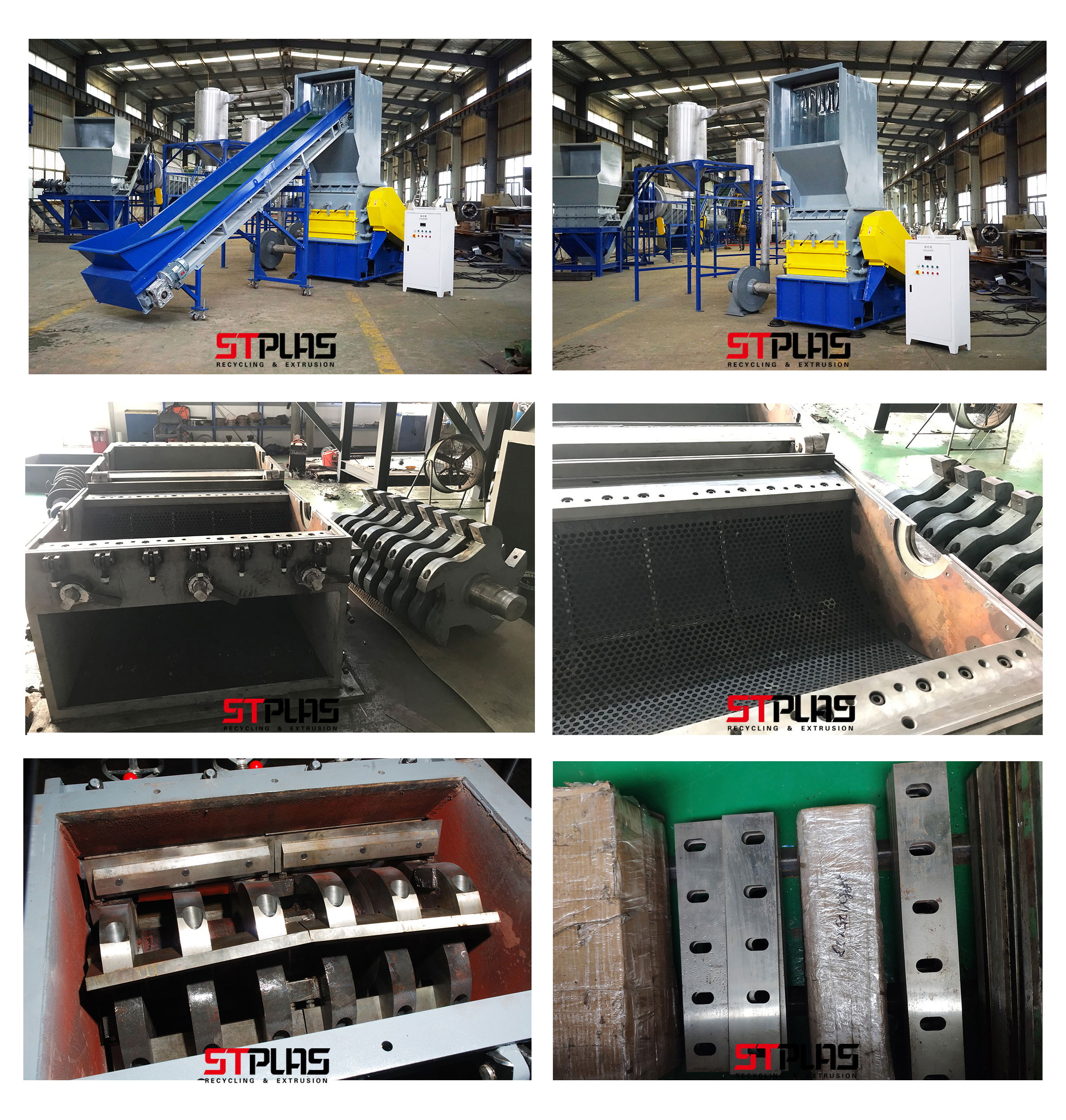

Crusher/grinder with water

Broken material

The size of the plastic bottle after crushing is φ12mm, the chipping rate is less than 3%

(Remarks: The chipping rate is one of the important criteria for judging the crusher because the more chips, the more the chips will be discharged from the production line with the friction washing and rinsing tank during subsequent cleaning, resulting in a great waste of raw materials. The unremoved parts will be at a very fast speed Blocking the screen of the subsequent dewatering machine causes the dewatering rate of the dewatering machine to decrease, increasing the cleaning speed of the screen and affecting the service life of the screen on the screen)

Crushing power: 37/55/75/90/110kw

For plastic bottle output 500/1000/1200/1500kgh

For film, the screen needs to be changed to φ40mm, and the output is halved(The output is the most intuitive criterion for judging the quality of the crusher)

Rotation diameter: φ500mm

Spindle length: 800mm-1200mm

(The rotating diameter and the length of the main shaft are the most important factors affecting the price of the crusher. At the same time, increase the rotating diameter: to φ500mm, it can completely prevent the film from being wound on the main shaft. The rotating diameter of other manufacturers is basically φ400mm or φ450mm)

Movable knife: 6 pieces (3 groups)

Fixed knife: 4 pieces (2 groups)

Blade structure: (The claw knife structure will prevent the occasional thick material from entering the crusher. The current will increase sharply and damage the electrical appliance. The mechanical force generated by the thick material is very likely to produce impact force. Other types of thin and long blade structure can be broken. Effectively avoid this problem) This is why many mid-to-high-end customers buy Chinese cleaning equipment instead of buying Chinese crushers. The knife structure of our company after years of improvement has been verified by users to be feasible.

Blade material: D2 service life is greatly improved, grinding once every three days, reducing equipment maintenance costs(The crusher is the second most important factor affecting the price of the crusher, and it is also an important factor affecting the output of the crusher)

In comparison: other manufacturers move knife: 8-10 piecesThe more blades, the more the manufacturer is not confident about the output, and the more blades will increase the maintenance cost and sharpening time. At the same time, the more blades will increase the risk of blade collision and increase the chipping rate)

In addition, in order to reduce the intensity and time of screen changing, our screen changing system adopts a hydraulic system. Other factories adopt electric methods. The mechanical force and hard force of the electric screen changing configuration will increase the risk of worker injury. Mechanical force will cause blade scratching. Injury)

Breaking with water: avoid the high temperature degradation of the blade, especially the filmWater spray can initially remove the sediment, reduce the pressure of the sediment on the rear track, and reduce the wear of the blade and the screen by the sedimentThe sprayed water can be sewage from the back